How to avoid the “tension” of threadbreaks.

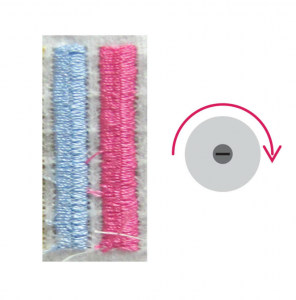

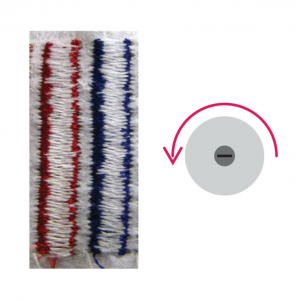

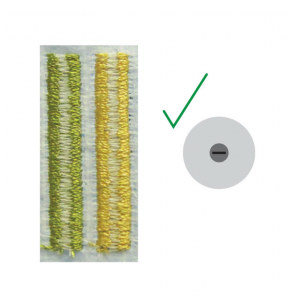

Proper thread tensioning is essential to good embroidery. Too loose, your thread will begin looping; too tight, bobbin thread may begin to show on top and you may begin to experience frequent thread breaks which wastes time and money. Before beginning your top thread tensioning, be sure to check your bobbin thread tension as this may lead to undesirable tension results of your top thread. Proper tensions for satin stitches should reveal 1/3 bobbin and 2/3 top thread colour on the underside of the embroidery.

|   |   |

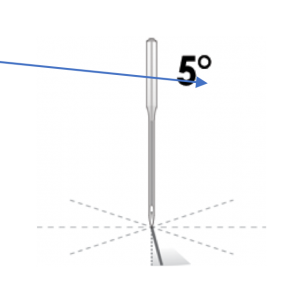

Thread breaks are irritating and slow the production down. A decent well-maintained machine should have very few thread breaks. Here is a checklist of common causes for thread breaks

|

|   |